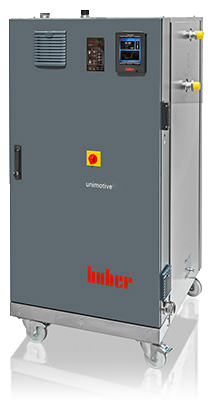

Automotive

High-precision temperature control solutions for the automotive industry

Particularly high requirements apply in the automotive industry. Researchers and engineers all over the world trust our temperature control technology because of the following features:

There are numerous applications for our temperature control units in the automotive industry. Typical areas of application are, for example, environmental simulations, material testing as well as temperature-dependent stress and load tests for materials, transmissions, bearings and engine parts.

Another frequent field of application is research tasks, test series and quality control on batteries, accumulators and electronic components. Researchers and engineers around the world rely on our temperature control technology for the design, construction and operation of test benches in the automotive industry.