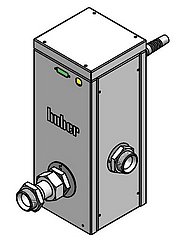

Unimotive GL 30w-XT

Temperature control system for Automotive applications

Performance Characteristics

The Unimotive model series is specially designed for applications in the automotive industry. The temperature control systems are designed for operation with water-ethylene glycol mixtures with corrosion protection (e.g. Glysantin®) down to -45°C. Typical areas of application are temperature simulations as well as material tests and temperature-dependent stress and load tests for automotive components and functional components. The optionally available "Flow Control Cube" enables precise flow rate measurement and control. Unimotive temperature control units are ideally suited for integration into test benches, where they ensure reproducible temperatures, e.g. for quality controls, battery tests, transmission and bearing tests as well as for temperature control of air conditioning and vacuum chambers and calibration tasks. Unimotive models impress with their unique thermodynamics for highly accurate and reproducible results. The proven Unistat technology also enables the shortest possible heating and cooling times and maximum temperature control accuracy for Unimotive units. All Unimotive models are operated via a colour 5.7" touchscreen display with convenient menu navigation.

The model variants "XT" are designed for operating temperatures up to +150 °C. Unimotive XT works with a fully integrated and variable pressure overlay that sets new standards. Overpressure in the fluid circuit can be set to a fixed value or as a ramp for ranges above the standard boiling point. The variable pressure overlay relieves the application at low temperatures by reducing the system pressure. No external pressurisation is required for operation, i.e. Unimotive XT does not require any special infrastructure (e.g. nitrogen gas tanks or similar).

The model variants "GL" (Green Line) work with the natural refrigerant carbon dioxide CO2 and are therefore a 100 % environmentally friendly alternative to units with synthetic refrigerants. Carbon dioxide (also known as R744) is a natural component of air and has been used in refrigeration technology since the 19th century. CO2 possesses a zero ozone depletion potential (ODP = 0), has a negligible global warming potential (GWP = 1) and is non-flammable, non-toxic and chemically inactive.

Functions overview

- Natural refrigerant CO2, environmentally and climate-friendly

- No ozone depletion potential, very low global warming potential (GWP = 1)

- Direct operation with water-ethylene glycol mixture with corrosion protection (e.g. Glysantin®)

- Pilot ONE controller with 5.7“ touchscreen and comfortable menu navigation

- Options for measuring and controlling pressure and flow rate

- Fast heating and cooling

- Highly accurate and reproducible temperature control results

- Adaptive temperature control, self-optimising

- Variable pressurisation for operating temperatures up to +150°C

- Highly efficient operation saves working time and operating costs

Product impressions

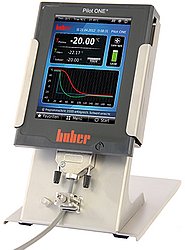

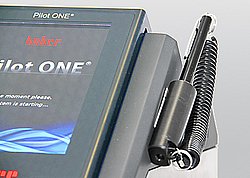

Controller

The new multi-touch controller Pilot ONE offers a brilliant 5.7" touchscreen with graphic functions and a comfortable navigation menu. All important operating parameters and temperature values are neatly displayed on the touchscreen. Thanks to the new favourites menu, the one-click operation and the integrated technical glossary the operation is very easy, just like on a smartphone. Integrated USB and Ethernet ports allows connection to a PC or network, e.g. for remote control or data transmission.

Read more

| Heating capacity | 24 | ||||||||||

| Cooling capacity |

|

||||||||||

| Refrigeration machine | water-cooled, natural refrigerant | ||||||||||

| Refrigerant 1st stage | R-744 (A1, H280) | ||||||||||

| Refrigerant quantity 1st stage | 8,7 kg |

| Delivery capacity pressure pump max. | 201 l/min; 5,3 |

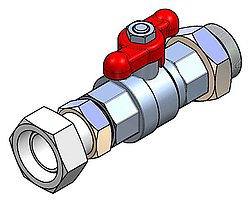

| Pump connection | M38x1,5 AG male |

| Max. permissible viscosity | 200 mm²/s |

| Pump speed adjustable | no |

| Pump type | magnetically coupled, stainless steel |

| Pump characteristics | Pressure pump, speed not variable, magnetically coupled |

| External sensor connection | Pt100 |

| Control input | ECS ONE |

| Control output (potential-free contact) | POKO ONE |

| Interface digital | Ethernet, USB (Host u. Device), RS232 |

| Permissible ambient temperature | 5...40 °C |

| Filling volume min. | 8,9 |

| Expansion volume | 19,9 |

| Cooling water connection | G3/4 male |

| Cooling water consumption at 15°C, flow 0°C | 3100 l/h |

| Cooling water differential pressure min. | 1 bar |

| Cooling water pressure max. | 6 bar |

| Power supply | 400V 3~ 50Hz |

| Current consumption max. | 62,5 |

| Fuse | 3x63A |

Please take further technical information as well as information about the scope of delivery, accessories and peripheral devices from the PDF data sheet. In cases of doubt the details given in there apply. If nothing to the contrary is quoted then the performance data referred is at an ambient temperature of 20°C.

Please observe the notes on installation and/or the space requirements of our products.

The following voltage and frequency tolerances apply based on EN60034-1:

Voltage +/- 5% for a frequency tolerance at the same time of +/- 2%

Examples to illustrate this: Not permissible, for example. is -5% on the voltage and +2% on the frequency. Permissible, on the other hand, are tolerances of -5% on the voltage and -2% on the frequency.

We reserve the right to make technical changes and correct errors. Illustrations can deviate from the original.